The analysis of the relation between loading and pile shaft displacement is an important factor to determine the pile bearing capacity.

In bi-directional static load test, Ougan will normally test three displacement positions:

1. Upper pile loading displacement;

2. Lower pile loading displacement;

3. Pile top displacement;

And how to test these displacements correctly, especially for upper pile and lower pile after loading, is the key factor to determine successful testing.

Ougan has original suggestion for upward displacement and downward displacement testing as below:

1. Position the displacement measurement point for upper pile and lower pile. Ougan didn’t locate the displacement measurement point of upper pile and lower pile on up and down surface of load cell, but in the position around 30cm-50cm above and below the load cell. Ougan think in some special cases, the actual displacement of upper and lower pile is not equal to the actual displacement of load cell. So locating the displacement measurement points on pile shaft instead of load cell can make sure the objectivity of displacement testing.

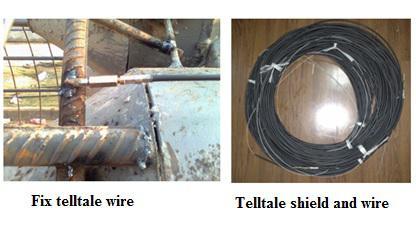

2. Several measurement points in same cross section. According to different diameter of pile, normally there are two or more telltale wires extended from testing cross section to pile top and fixed with special device, then displacement data of each wire can be recorded simply and precisely.

3. Joint-free telltale shield and telltale wires. Telltale wire is made of high tensile strength steel wire, and telltale shield is with three layers protection. Easy installation, joint free, free movement of internal telltale wire and shield’s strong protection to wire from concrete squeezing are main features of Ougan displacement measurement. And no butt joint is required for telltale wire ropes when lower reinforcement cage, wire ropes only need to be fixed along the cage up to ground. So it avoids the test failure caused by human mistake in telltale wire and shield joint butting.